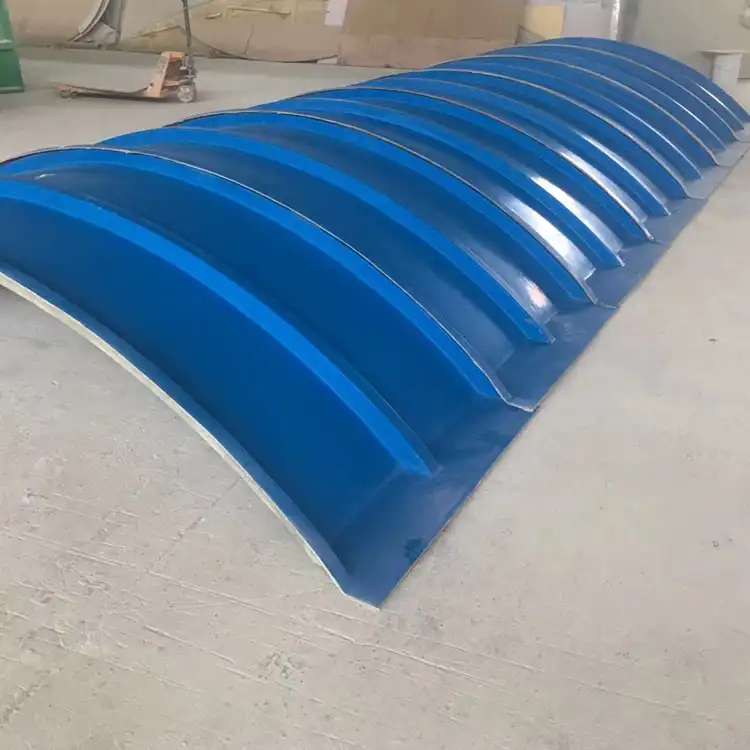

FRP anti-odor barrel vault wagon vault tunnel vault arch cover plate is mainly used in sewage treatment system engineering, petrochemical industry, etc. Because of FRP characteristics of corrosion resistance, light weight and high strength, aging resistance, designability, easy installation and long service life, FRP barrel vault wagon vault tunnel vault arch cover plate has been widely used in the development of modern society. According to the requirements of users and the size of the cesspool According to the user’s requirements and the size of the cesspool, the curved cover is made. The color can also be made into a variety of colors according to the demand to meet the different needs of users. The color can also be made into various colors according to the demand to meet the different needs of users.

FRP barrel vault rain cover

FRP barrel vault rain cover is also called FRP sewage tank cover, FRP barrel vault cover: it is composed of outer surface layer, reinforcement layer and inner surface layer structure. The outer surface layer is the contact layer with the atmosphere and sunlight, which needs to be anti-aging, anti-UV and beautiful and generous, with thickness not less than 0.3mm. It adopts gel coat resin. The middle layer is the FRP cover, bearing rain, snow and personnel maintenance of the load structure layer. The main stress layer needs to have sufficient strength margin, and the reinforcement layer is selected from unsaturated polyester resin 3301 to do the matrix, and alkali-free glass fiber square cloth to do the reinforcement. The inner surface layer (rich resin layer) is a layer in contact with the corrosive gas in the pool, the layer needs to have a temperature-resistant, corrosion-resistant, impermeable, anti-static inner surface rich resin layer. The inner surface rich resin layer is made of vinyl ester antistatic resin, glass fiber alkali-free short-cut felt, containing not less than seventy-five percent of rubber, the thickness of not less than 1.5 mm. FRP barrel vault cover production: one-time molding process.

FRP arch cover

1. FRP arch cover is also called sewage tank cover, due to its excellent mechanical properties of light weight, high strength, high corrosion resistance and aging resistance, as well as designability, is increasingly becoming the mainstream material for chemical corrosion, sewage treatment and other industry applications. Its relative density is between 1.5 and 2.0, but its tensile strength is close to or even exceeds that of carbon steel, while its strength can be compared with that of senior alloy steel. FRP is a good corrosion-resistant material, with good resistance to the atmosphere, water and general concentrations of acids, alkalis, salts, as well as many kinds of oils and solvents. FRP arch cover in technological innovation, through the development of new curing formula and process, the development of the cover body activity cover, observation window, access holes, sampling holes, etc., not only makes the product strong, corrosion resistance, flame retardant, to further meet the needs of the oversized span pool body, but also convenient for the user sampling, maintenance.

2. Low cost and long service life: compared with other cesspool deodorization programs, the cost is low and the installation and construction is simple.

3. Excellent corrosion resistance: acid and alkali resistant, corrosion resistant resin as the base material made, using excellent curing formula, advanced curing process, according to the shape of the condition of each cesspool, to determine the specific mold as a molding outer mold curing molding.

4. Excellent thermal insulation performance: Because of the low thermal conductivity of FRP, this FRP equipment can achieve good thermal insulation performance without additional insulation structure. FRP exterior is made of anti-aging, weathering and UV resistant gel coat resin, with smooth, beautiful and bright color surface.

5. Light weight and high strength, easy to install: FRP products are very high strength. The cover is assembled in blocks to facilitate manual handling for disassembly. Between each piece of cover and between the cover and the top surface of the pool should be sealed connection to prevent odor leakage.

6. designability: according to the specific situation of the site pool, the size of the product can be designed flexibly, the shape can be made into an arc-shaped cover, round cover, etc., and its color can also be made into a variety of colors according to demand, to meet the different needs of users.

FRP wagon vault sealing cover

FRP sedimentation basin cover

FRP cambered cover

FRP sewage tank gas collection cover

Fiberglass gas collection cover