Our company produces FRP integrated sewage treatment plant adopting biological treatment process, set to BODs COD NH3-N in one unit. It is widely used in sewage treatment of senior hotels, villas, residential areas or similar industrial organic sewage treatment, with superior corrosion resistance.

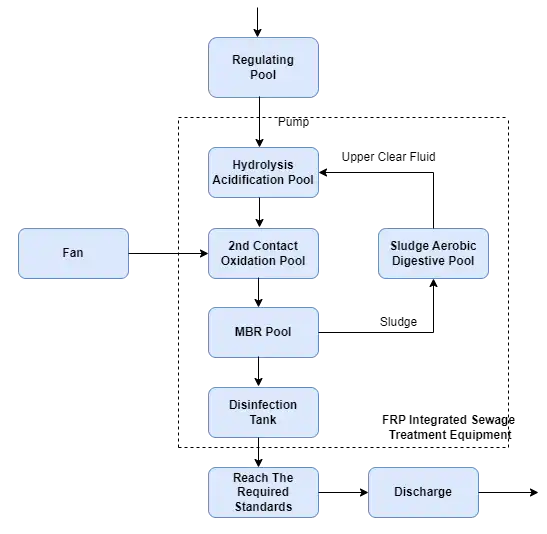

[A20+MBR process] - Anaerobic + Anoxic + Aerobic + MBR film

In this process, there is a reflux, one section of the film tank mixture is returned to the anoxic tank for denitrification and the other section is returned to the anaerobic tank for anaerobic phosphorus release. The traditional biological denitrification process usually uses front-loaded denitrification or back-loaded denitrification to achieve nitrogen removal, while the A20 process with anaerobic anoxic and aerobic reactors can achieve simultaneous nitrogen removal and phosphorus removal.

The high concentration of MLSS in the A20+MBR process independently controlled hydraulic retention time and sludge retention time reflux ratio and sludge loading rate will have a different impact from the traditional A20 process with better nitrogen removal and phosphorus removal efficiency. The A20+MBR process with simultaneous nitrogen removal and phosphorus removal combined by A20 process and film separation technology can further expand the application scope of MBR.

Emission Standard

Grade 1 Class A discharge standard, domestic wastewater treatment equipment using the process: A-0-0 biological contact oxidation + MBR + disinfection

The film treatment method is the core of the combined film bioreactor process. The application of film technology in wastewater treatment not only can effectively purify wastewater, but also can recover some useful substances, and has the characteristics of energy saving, no phase change, simple equipment, easy operation, etc. The film separation process is based on the selective permeable film as the separation medium, and some kind of power is applied on both sides to selectively permeate the raw material components through the film, so as to achieve the purpose of separating substances. The effluent quality can reach the national standard of miscellaneous water quality, and the treatment method has the advantages of small footprint, simple operation and stable effluent quality.

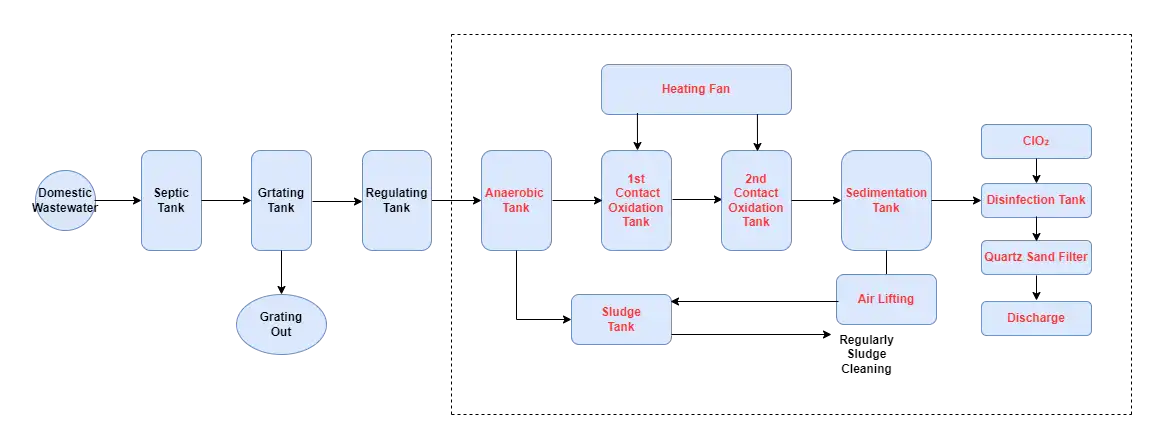

Grade 1 Class B discharge standard, domestic wastewater treatment equipment using the process: A-O-O biological contact oxidation + filtration + disinfection

Mechanical filtration tank filled with quartz sand, quartz sand and the combination of the filter container, used to retain suspended matter in the water colloid and other particle impurities, to play a certain role in filtration. The activated carbon filter is filled with activated carbon, whose main function is to purify the small impurities in the water, filter the color value of the water, remove the odor in the water, etc. Through the double treatment of mechanical filter tank and activated carbon filter, the suspended matter and chromaticity of the sewage are greatly improved.

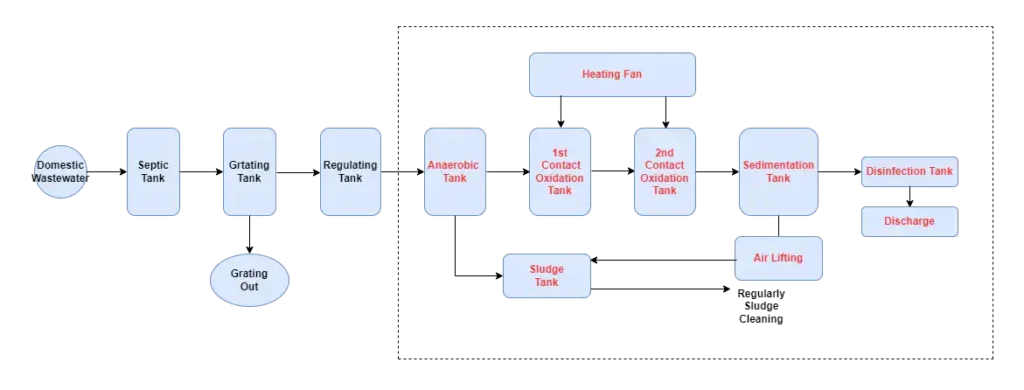

Grade 2 discharge standard, domestic wastewater treatment equipment using the process: A-O-O biological contact oxidation

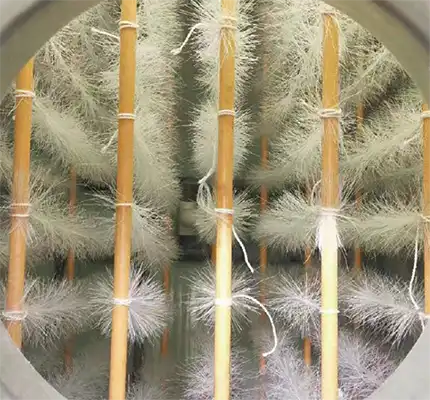

The biological contact oxidation method is a biological treatment method derived from the biofilm method, i.e. the biological contact oxidation tank is filled with a certain amount of fillers, and the organic matter in the wastewater is oxidized and decomposed through the biological oxidation by using the biofilm attached to the fillers and the sufficient supply of oxygen to achieve the purpose of purification. In the anoxic section, heterotrophic bacteria hydrolyze soluble organic matter in the wastewater into organic acids, decompose large organic matter into small organic matter, convert insoluble organic matter into soluble organic matter, and oxidize pollutants such as proteins and fats (N in organic chain or oxygens in oxyacids) to release oxygen (NH3, NH4+). In the aerobic section, aerobic microorganisms and autotrophic bacteria (digestive bacteria) exist, where aerobic microorganisms decompose organic matter into CO2 and H20; under adequate oxygen supply conditions, the nitrification of autotrophic bacteria oxidizes NH3-N (NH4+) to N03-, which is returned to the anoxic section through reflux control, and under anoxic conditions, denitrification of heterotrophic bacteria reduces N03- to molecular state oxygen (N2) to complete the cycle of C, N and O in the ecology and realize the harmless treatment of wastewater.

Packing & Frames

MBR Film

Aerator